Electric power utilities will generally experience a problem with the age of the equipment and all the infrastructure, of course, this will lead to increased risk of blackouts (outages total) and brownouts (appliances burning or exploding), unexpected costs will increase dramatically for the repair / maintenance, number of security problems to a location away from the scrutiny, and will certainly lead to huge cost overruns.

As one part of an initiative to improve public services, electricity industry is always looking for a way out of these problems which of course will support efforts to increase the reliability and quality of electrical power supply but still can save the cost of an abundant discharge.

We also try to participate in this effort by working with several business partners, manufacturers and the distribution in order to improve monitoring systems in electrical substations.

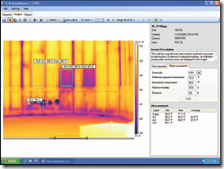

Through the use of an Infrared Camera "smart" we are trying to improve intelligence (artificial intelligent) and analysis of the more intelligent automation software to meet the electricity needs of an increasingly complex industry. Failure of equipment that will happen someday and security problems of a site would be easily detectable at any time, day or night, even though the location of any remote monitoring. The result will be found an increased reliability and reduced costs that are not supposed to.

Through the use of an Infrared Camera "smart" we are trying to improve intelligence (artificial intelligent) and analysis of the more intelligent automation software to meet the electricity needs of an increasingly complex industry. Failure of equipment that will happen someday and security problems of a site would be easily detectable at any time, day or night, even though the location of any remote monitoring. The result will be found an increased reliability and reduced costs that are not supposed to.

Early warning against a wide range of problems in the substation:

- Remote monitoring of vital and critical component in an electrical substation.

- Can help improve performance and reliability without adding personnel ThermoVision.

- Monitoring can be done from the central control room and can be integrated easily with Substation Automation System via Ethernet (TCP / IP) and nirkable connection (wireless).

- ThermoVision images can be viewed directly through a computer monitor (LIVE) substation automation or with a separate server module.

- Get temperature readings quickly and accurately from the excess heat from the equipment (overheating) and is expected to burn within a certain time.

- Able to observe the equipment was not working anymore (damaged) by appointment at a much lower temperature than other equipment.

- Able to produce audio-visual alarm from either internal or via software Substation Automation.

- Can send reports via email and automatic notification to management intranet connection for faster action. Or you can also SMS-Alert method-Dial Phone, or to related parties if the infrastructure is still inadequate.

- Work in any condition, on the day or night, whether hot or too wet and can operate for 24/7.

Typical System Configuration

Automation system this time deliberately designed specifically for circuit monitoring equipment in substations and critical enough with age that can be burned at any time. Methods and models thermovisi depiction taken from the IR camera can follow the standards and the needs of end-user. Automation system we designed is an open architecture that can be developed into a wide range of models and sustainable development for the best reliability of a system.

Melalui .Net Framework, pengembangan ke dalam intelligent automation system jauh lebih mudah dan tak terbatas dibandingkan dengan yang lainnya, vista & win 7 support plus tampilan gambar 64bit (HD), web-application, dll. Dan tentu saja “Free-License”, sehingga anda dapat menggunakan investasi ini selamanya tanpa batasan waktu. Karena kami menyadari license key terkadang malah seringkali menyebabkan error dan cenderung membingungkan end-user.

Kami tidak hanya merancang aplikasi automation untuk substation saja, namun bisa juga untuk beragam aplikasi pemantauan lokasi kritis lainnya seperti: Oil & Gas, Power Generation, Hi-Risk Building, dll. Untuk saat ini, kamera IR yang compatible dengan intelligent automation system yang kami desain adalah FLIR A-Series.

With the addition of an integrated controller with IR camera housing to adjust the viewing angle and the slope of the IR camera will facilitate monitoring of the substation site. Intelligent Automation System can control and the intelligent controller is able to perform site-automatic patrol, monitoring equipment and temperature monitoring site security without human supervision.

The images obtained will be sent via Ethernet, wireless or fiber optic. Intelligent Automation System can also be programmed to automatically generate periodic reports as required and end-user format to ensure system reliability.

Automated Substation Monitoring Systems

Here are some of the substation components that can be monitored remotely where equipment failure can be identified by thermal and equipment can be monitored in see-through:

Automated Substation Monitoring Systems

Here are some of the substation components that can be monitored remotely where equipment failure can be identified by thermal and equipment can be monitored in see-through:

- Power Transformer / Power transformers (transformer oil level and pump operation)

- Load tap changers (level of oil and other internal problems)

- Insulator bushings (oil level and the detection of faulty connection or poor)

- Standoff insulators (moisture, contamination, and degradation)

- Lightning / Surge arrestors (degradation in metal-oxide disk)

- Circuit breakers / PMT (leakage of oil or SF6)

- Mechanical disconnects: DS, ES, etc. (poor connection or damaged, contamination)

- Control cabinets (kerusakanyang caused by the fan, pumps and other components)

- Battery

0 komentar:

Posting Komentar